-

Add: HeBei ShengShi HongBang Cellulose Technology CO.,LTD.

-

Email

13180486930@163.com -

CONTACT US

+86 13180486930

Understanding Methyl Cellulose and Its Pricing Dynamics Methyl cellulose, a water-soluble polymer derived from cellulose, has garnered increasing attention in various industries due to its versatile properties. As a key ingredient in food, pharmaceuticals, cosmetics, and construction, methyl cellulose plays a significant role in enhancing the quality and functionality of many products. However, the pricing aspects of methyl cellulose often raise questions among manufacturers and consumers alike. This article delves into the factors influencing the price of methyl cellulose, its applications, and the market trends that shape its economics. What is Methyl Cellulose? Methyl cellulose is produced through the methylation of cellulose, which is a natural polymer obtained from plant cell walls, particularly from wood and cotton. This modification process endows methyl cellulose with unique properties such as high viscosity, gelling ability, and water retention. Because of these characteristics, it acts as a thickener, emulsifier, and stabilizer, making it a popular choice in various applications. Applications of Methyl Cellulose 1. Food Industry Methyl cellulose is commonly used in the food industry as a thickening agent and a fat replacer. It helps improve the texture and stability of food products like sauces, dressings, and baked goods. Additionally, its ability to form gels at elevated temperatures is exploited in vegetarian and vegan food substitutes. 2. Pharmaceuticals In the pharmaceutical sector, methyl cellulose serves as an effective binder, coating, and disintegrant in tablet formulations. Its water-retaining properties are also valuable in the production of ocular solutions and laxatives. 3. Cosmetics Methyl cellulose is utilized in various cosmetic products for its thickening and stabilizing properties. It can be found in shampoos, lotions, and creams, contributing to the desired texture and overall feel of these products. 4. Construction The construction industry employs methyl cellulose as an additive in tile adhesives, joint compounds, and plaster. Its water retention and improved workability aid in creating durable and effective building materials. Factors Influencing the Price of Methyl Cellulose harga metilselulosa The pricing of methyl cellulose is influenced by several key factors, including 1. Raw Material Costs The primary raw materials for cellulose-based products, including cotton and wood pulp, can experience price fluctuations based on supply and demand dynamics. In addition, any changes to regulations affecting sustainable sourcing can also impact raw material costs. 2. Production Processes The manufacturing processes involved in producing methyl cellulose can be complex and energy-intensive. Advances in production technology can potentially reduce costs, but any disruptions—such as maintenance issues or the introduction of new regulations—can affect pricing. 3. Market Demand The growth of industries utilizing methyl cellulose directly impacts its demand. For instance, the rising popularity of plant-based food products has significantly increased the use of methyl cellulose as a vegan binder in food processing, contributing to fluctuating prices. 4. Geopolitical Factors International trade agreements, tariffs, and political stability in regions producing cellulose can affect the global supply chain, impacting both availability and pricing of methyl cellulose. For example, disruptions in trade can lead to supply shortages, subsequently driving up prices. 5. Technological Innovations As research advances, new grades and formulations of methyl cellulose are developed, often commanding different price points. Innovations that enhance performance or functionality can justify higher costs, while more efficient production methods can lower them. Market Trends and Future Outlook The methyl cellulose market is poised for growth, driven by expanding applications across various sectors. The trend toward clean label products in the food industry, coupled with an increasing preference for natural and plant-based ingredients, is likely to sustain demand for methyl cellulose. Additionally, advancements in production technology and heightened environmental awareness may foster more sustainable practices within the industry, influencing pricing trends. In conclusion, methyl cellulose plays an invaluable role across numerous industries. Understanding the factors that contribute to its pricing can help stakeholders make informed decisions. As demand for this versatile polymer continues to grow, staying attuned to market trends and shifts will be essential for navigating the complexities of methyl cellulose pricing.

- 40000tons

Production

- 20+years

Experience

- 5000+㎡

Acreage

-

In the competitive realm of building materials and construction, the name HPMC easily resonates with industry insiders. HPMC, or Hydroxypropyl Methylcellulose, has a significant role, not just in construction, but also in other applications like pharmaceuticals and food products. However, the focus here is specifically on the construction product line and its branding identity, represented by the HPMC logo. The HPMC logo symbolizes innovation, quality, and reliability—a trifecta that every construction professional seeks. Through its unique visual identity, the HPMC logo encapsulates the essence of the brand, which is committed to enhancing the quality and longevity of construction projects globally. This symbolic representation differentiates it from competitors, offering a mark of excellence. Experience with HPMC products starts right from the visual interaction with its logo, often the first point of contact for potential customers or business partners. This logo becomes a beacon of trust . When adorned on packaging, brochures, or digital platforms, it assures clients of the consistent quality embedded in HPMC’s comprehensive portfolio of cellulose ethers, used extensively in cement, gypsum, and ceramics. For experts in the construction industry, the HPMC logo is a signifier of unparalleled expertise. Hydroxypropyl Methylcellulose has unique qualities such as water retention, thickening, and binding abilities, which are crucial in sustainable construction practices. The experts developing HPMC have engineered its products to perform efficiently under diverse environmental conditions, ensuring the stability and durability of constructions. Authoritatively, HPMC stands head and shoulders above others in the realm of cellulose ethers. Its logo is a testament to years of research and development. The technological advancements encapsulated by HPMC have been recognized by industry leaders, accrediting it as a go-to material for high-performance construction solutions. Its use in high-rise buildings, bridges, and other complex infrastructures underscores its authority in the field. The trustworthiness of the HPMC brand can be attributed in part to the consistent representation and quality assurance denoted by its logo. In an industry where safety and reliability are paramount, the HPMC logo comes to signify peace of mind. Construction professionals rely on this assurance, knowing that adherence to strict quality control protocols backs every product marked with the HPMC insignia. hpmc logo HPMC's products are not just made; they are crafted, with each batch being a testament to the company’s commitment to excellence. The meticulously designed logo is an assurance that whether you're working on small-scale renovations or large-scale infrastructural endeavors, the materials you use will perform to the highest standards. Additionally, the HPMC logo also plays a role in sustainable construction solutions. With increasing demand for environmentally responsible building practices, products bearing the HPMC logo are often formulated to reduce environmental impact. This contributes significantly to LEED certifications and other green building standards, enhancing the credibility of projects and ensuring compliance with global sustainability goals. In essence, the HPMC logo does far more than signify a product line—it tells a story of dedication to performance, innovation, and integrity. It is an emblem that carries forward the core values and unparalleled standards of HPMC, offering an edge in the competitive market landscape. The brand's commitment to research and development further underpins its potential to lead in innovative solutions, continually setting standards for quality in the construction industry. The symbiotic relationship between the HPMC logo and its promise of quality underscores a value proposition that competitors aspire to—and customers trust unwaveringly. Builders, architects, and contractors around the globe look to this symbol with confidence, knowing that the materials they choose will deliver exceptional performance, project after project. Overall, the HPMC logo not only reflects the company's expansive expertise and authoritative standing in the industry but also reinforces its commitment to reliability and trustworthiness. It represents a blend of technological innovation and proven performance, making it a vital asset to construction professionals worldwide.

-

Rubber powder coating has quietly risen to prominence in the coating industry, capturing the interest of manufacturers and DIY enthusiasts alike. Its increasing popularity stems from its remarkable ability to provide a durable, protective layer with a unique set of properties that traditional coatings fail to offer. This article delves into the technicalities, benefits, and applications of rubber powder coating, shedding light on why it’s becoming a go-to choice in diverse sectors. Rubber powder coating combines the resilient and flexible properties of rubber with the robustness of a powder coat . Unlike liquid coatings which rely on solvents and VOCs (volatile organic compounds), rubber powder coatings are applied in a dry powder form and cured under heat or with ultraviolet light, allowing for a safer and more environmentally friendly process. This method not only reduces harmful emissions but also minimizes waste, which is an attractive advantage in today’s environmentally conscious market. From an expert's perspective, one of the standout features of rubber powder coating is its elasticity. This means that the coating is capable of expanding and contracting without cracking, making it particularly beneficial in environments subject to extreme temperature variations or mechanical stresses. The elastic nature ensures a continuous and protective barrier even when the substrate underneath is in constant motion. In terms of applications, rubber powder coating is incredibly versatile. It finds use in automotive and marine industries where its resistance to abrasion and corrosion is highly valued. The coating effectively protects metal surfaces from rust and pitting, extending the lifespan of components like vehicle underbodies and marine hardware. Moreover, the construction industry utilizes rubber powder coatings for tools and equipment that face wear and tear, leveraging its anti-slip properties to enhance safety. The application process of rubber powder coating further contributes to its growing popularity. It can be applied at varying thicknesses to suit different performance needs without compromising on quality. Lower thicknesses are optimal for projects requiring finesse, while higher builds offer superior protection for heavy-duty applications. This flexibility allows businesses to tailor their approach based on specific requirements, optimizing both performance and cost-efficiency. rubber powder coating Adding to its list of advantages, rubber powder coatings are available in a multitude of colors and finishes, which widens its appeal for aesthetic applications. From homeware to consumer electronics, its potential to offer both protection and style makes it a preferred choice among manufacturers looking to innovate product design without sacrificing quality. In reinforcing trustworthiness, manufacturers and applicators of rubber powder coatings emphasize rigorous quality control standards and thorough testing to ensure each batch meets stringent performance criteria. Customers are assured of receiving reliable and consistent products that meet or exceed industry standards. Furthermore, adherence to environmental regulations and sustainable practices in production processes bolsters the credibility and authority of companies in this market. Finally, the ease of maintenance associated with rubber powder coatings cannot be overlooked. Its seamless finish makes it resistant to dirt and contaminants, and should cleaning be necessary, the surface can be easily wiped down with minimal risk of damage. This attribute is particularly appealing in high-traffic areas or environments where hygiene is paramount. In essence, rubber powder coating represents a fusion of innovation and practicality. Its amalgamation of elasticity, environmental compatibility, and customization potential positions it as the future of protective coatings. By integrating these features, industries stand to not only enhance product longevity and performance but also align with the growing trend towards sustainable solutions. As the market evolves, the role of rubber powder coating will undoubtedly expand, paving the way for further innovations that meet the demands of tomorrow’s challenges.

advantages

-

200000 Viscosities

Excellent product

We can produce pure products up to 200,000 viscosities

-

40000 tons

High yield

We don’t stop production all year round, and the annual output can reach 40,000 tons

-

24 hours

Quality service

We provide 24-hours online reception service, welcome to consult at any time

———— Inquiry Form

Schedule A services

-

is_cellulose_wood_pulp

is_cellulose_wood_pulpOct . 25, 2025

Hydroxypropyl methylcellulose (HPMC) E15 is a versatile polymer used widely in various industries du -

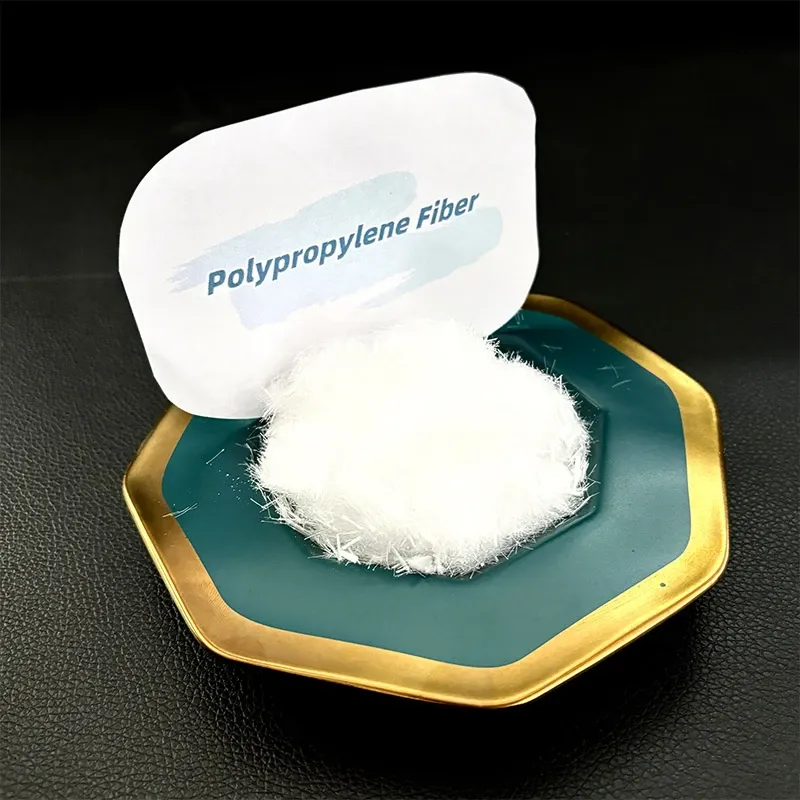

man_made_synthetic_fibers

man_made_synthetic_fibersOct . 25, 2025

Hydroxypropyl Methylcellulose (HPMC) stands as an innovative polymer solution , lauded for its multi -

hpmc_e5_uses

hpmc_e5_usesOct . 25, 2025

Hydroxypropyl Methylcellulose (HPMC) sheets are increasingly recognized for their versatile applicat